Aim:

To study the performance characteristics of a single acting reciprocating pump test rig

Apparatus:

1. Reciprocating pump test rig

2. Stop watch

Formulae:

1. Theoritical discharge, `Q_{th} = \frac{V_{s}N}{60}` m3/sec

2. Actual discharge, `Q_{act} = \frac{AR}{T}` m3/sec

3. Pump input, `P_{i}=\frac{3600(n)}{EMC(t_{n})}` kW

4. Shaft power, `P_{s} = ` `mo t o r` `efficiency` X `P_{i}` kW

5. Pump output, `P_{o} = \gammaQH_{m}` kW

6. Pump efficiency, `\eta_{p}=(\frac{P_{o}}{P_{s}})` X `100`

7. Overall efficiency, `\eta_{o}=(\frac{P_{o}}{P_{i}})` X `100`

8. Slip percentage ` = \frac{Q_{th}-Q_{act}}{Q_{th}}` X `100`

where,

Vs = Volume of water discharge per stroke in m3= AsL

As = Cross sectional area of the piston in m2 = πD2/4

D = Diameter of the piston cylinder in m

L = Length of stroke in m = 2r

r = Crank radius in m

N = Speed of the pump in m

A = Cross-sectional area of the collecting tank in m2

R = Rise of water level in the collecting tank in m

T = Time taken for R m rise in the collecting tank in sec

n = Number of revolutions of energy meter disc

tn = Time taken for n revolutions in sec

EMC = Energy meter constant

γ = Specific weight of water = 9810 N/m3

Hm = Manometric head in m = Hs+Hd+Hf

Hs = Suction head in m = (Ps/1000)x13.6

Hd = Delivery head in m = 10xPd

Hf = Head loss due to friction in m

Ps = Suction pressure in mm of Hg

Pd = Delivery pressure in kg/cm2

Theory:

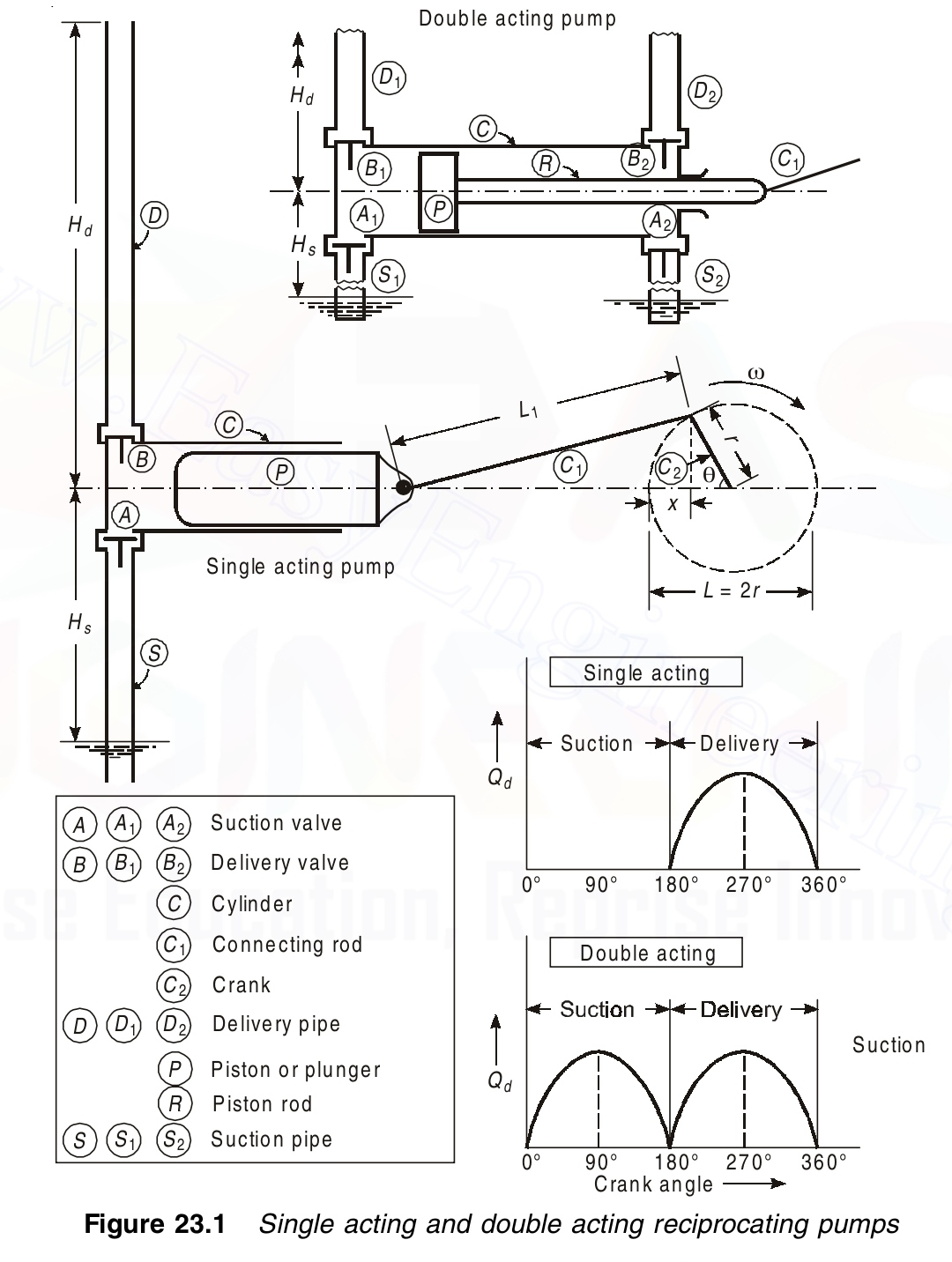

The reciprocating pump is a positive displacement pump which operates on the principle of actual displacement or pushing of fluid by a piston that execute s a reciprocating motion in a closely fitting cylinder.The liquid is alternatively-

(i) drawn from the sump and filled into suction side of the cylinder.

(ii)led to the discharge side of the cylinder and emptied to the delivery pipe.

The piston or plunger gets its reciprocating motion (moves backward and forward) by means of a crank and connecting rod mechanism.

Working:

The rotation of the crank causes the plunger to move backward and forward in the cylinder. Vacuum is created in the cylinder as the plunger moves to the right during suction stroke. The atmospheric pressure on the water surface forces the water up the suction pipe. The suction valve is opened and the water enters the cylinder. On the return stroke of the plunger called delivery stroke, the water pressure closes the suction valve and opens the delivery valve, forcing the water up the delivery pipe. Again in the suction stroke the water is sucked from the sump and the cycle continues.

Procedure:

1. Prime the pump, close the delivery valve and switch on the unit.

2. Open the delivery valve and maintain the required delivery pressure. Note the delivery gauge pressure reading and the corresponding suction pressure gauge reading.

3. Close the drain valve of the collecting tank and record the time taken for 10 cm rise in the collectig tank.

4. Open the drain valve of collecting tank and record the time taken for 2 revolutions of the energy meter disc.

5. Repeat the above procedure for different delivery pressures by manipulating the delivery valve.

Observations:

Cross sectional area of the collecting tank, A = .......... m2

Speed of the pump, N = .......... r.p.m

Radius of the crank, r = .......... m

Length of the stroke, L = .......... m

Energy meter constant, EMC = .......... rev/kW-h

Diameter of the cylinder, D = .......... m

Table:

| SNo. |

Pd (kg/cm2) |

Ps (mm of Hg) |

T (sec) |

tn (sec) |

Hm (m) |

Q (m3/sec) |

Pi (kW) |

Ps (kW) |

Po (kW) |

ηp (%) |

ηo (%) |

slip (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ||||||||||||

| 2 | ||||||||||||

| 3 | ||||||||||||

| 4 | ||||||||||||

| 5 |

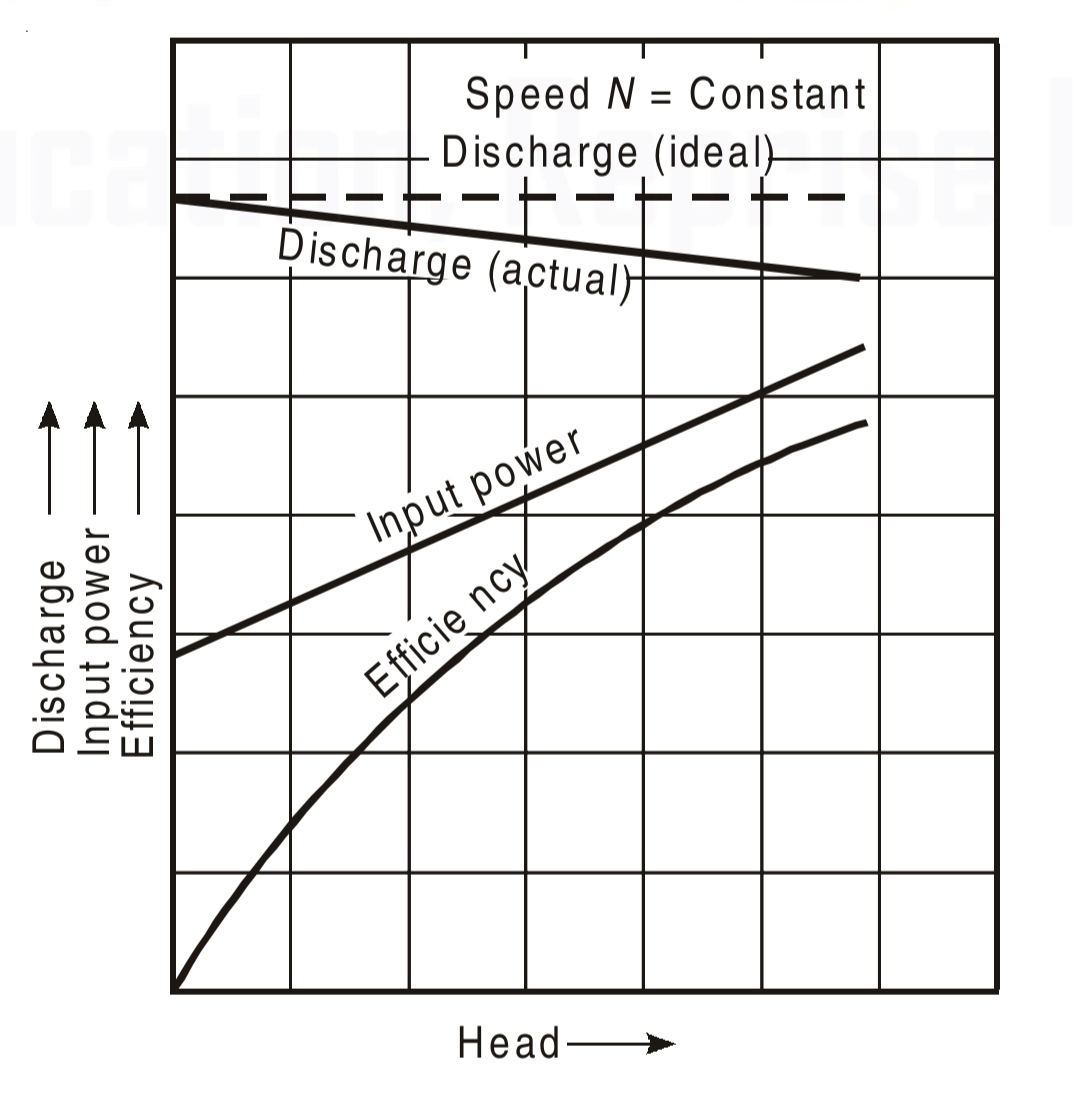

Graphs:

Graphs are plotted between,

a) Q Vs H

b) Pi Vs H

c) ηo Vs H

d) Percentage of slip Vs Q

Precautions:

1. Check for the priming of the pump so that the air bubbles are not developed.(In the supplied apparatus a self- priming pump is used so the pump does not require priming.)

2. Sufficient time should be given for the flow to become steady uniform.

3. Apparatus should be in levelled condition.

4. Piezometric scale readings should be recorded at eye level.

Result:

The performance characteristics of reciprocating pump have been studied and the

a) Overall efficiency of the pump, ηo = .......... %

b) Percentage of slip of the pump = ..........